- +20224519934

- [email protected]

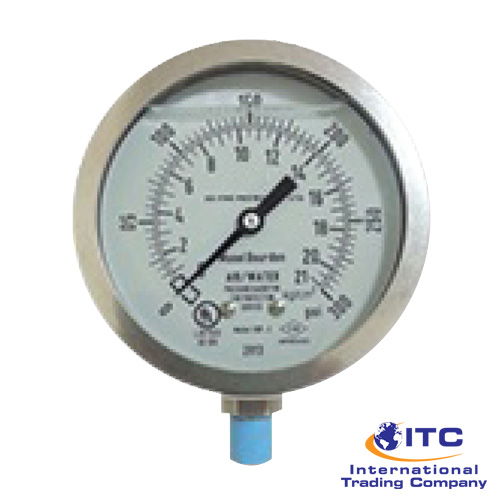

Pressure Gauges are specifically designed for Fire Sprinkler Services. Model FGP & FGP-1 has corrosion resistant polished stainless steel case and Bazel and Brass wetted parts. Model FGP- 2 is having Monel internal and Glycerine filled for sea water application. The dial has pressure reading in KG/SQCM and PSI. The gauge window is hardened glass.

Description

TECHNICAL DATA

DIAL SIZE – 100 MM (4”)

CONNECTION 1/4” NPT (Optional)

RANGE – 0 to 21Kg./Sq.Cm & 0-300 PSI

BURDON TUBE & WETTED – Monel

DIAL TYPE White background black graduation scale with dual reading in Kg./ Sq.Cm and PSI

CASE AND BAZEL Glycerine filled.

MOUNTING Direct

WINDOW Hardened Glass

ACCURACY +/- 2% of FSD for middle half of scale

WEIGHT (Approx) 0.8 Kg

REFERENCE STANDARD FM Standards, NFPA-13

ORDERING INFORMATION Specify connection & Model

The pressure gauge must be mounted by square provided for spanner grip on the socket and not by turning the case. Turning of case will damage the gauge. Use PTFE tape around male threads of the gauge for sealing. Pressure gauge must be mounted in vertical position and isolated with valve or cock. The pressure gauge must be handled with due care. For best results , the storage as well as any further shipment be made in original packing only. The pressure gauge, which is visibly damaged, should not be installed. It is recommended that the pressure gauges must be inspected regularly for possible corrosion or damage. The gauge must be periodically calibrated as per requirement of NFPA/TAC or as per local authority having jurisdiction.

CAUTION

1) Do not over tighten the Gauge

2) Do not tighten the gauge by holding dial.

Always use spanner to tighten.

Note: Pressure guages are mass calibrated, hence individual calibration certificate in not provided.

Pressure Gauges

Gauges for sprinkler systems and fire pumps are designed for use with air or water. These gauges are usually of the Bourdon tube type. The moving parts are fabricated of appropriate corrosion-resistant materials. When installed on the air side of a dry pipe system, a retard type gauge may be used. This gauge is assembled with a tube appropriate to the unretarded pressure range of the gauge and is provided with a spring to resist the full scale load. The two common sizes are 4 1/2 and 3 1/2 in. diameter. These gauges can be calibrated with a hydraulic testing unit by adjusting the dial pointer to read correctly at known pressures. Accuracy requirements are that the gauge be correct within 2% over the center third of its scale and within 3% over the remaining two-thirds. Dial marking subdivisions correspond to the maximum accuracy of the gauge. For service on fire pumps where the suction may be taken under a lift, compound pressure vacuum gauges are available graduated in pressure units over both the pressure and vacuum scales, and are designed not to be injured by vacuum. To minimize possible damage and provide maximum accuracy, gauges should be selected with scales of about twice the maximum system pressure.

Share this product

Related Products